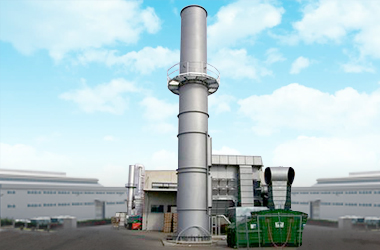

İndustrial chimney systems

13084 - 7

Industrial Chimney Systems Today, almost in all industrial production facilities professionally des...

Stainless steel chimney systems

1856 - 1

Stainless Steel Chimney Systems Chimney systems are designed to transmit the waste gases of heating...

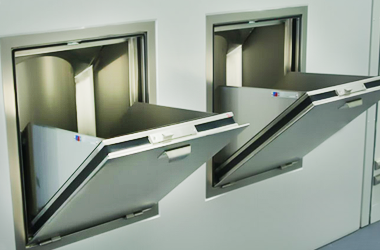

Garbage and Laundry Chute Systems

..............

Garbage and Washing Chute Systems Moving garbage and laundry in buildings such as large residences,...

Who did we work with?